Induction modules can be used as standalone cooking hobs. They also fit into a Rieber EST servery counter system or are used with the Rieber Varithek ACS front cooking system, usually supplied with ACS (Air Clean System) self-ventilation. Amerex fire suppression is another option.

Rieber Varithek cooking modules are versatile, slot-in cooking modules that support an enormous range of menu options.

The modules provide reliable, digitally controlled 3.5kW or 5kW power.

Full surface GN 1/1 and bullseye induction hobs

The full GN 1/1 induction hob is designed to work with Rieber’s complimentary range of GN pans (Rieber is the world’s largest maker of GN pans). For example, typically supplied with the 1/1 GN induction hob is the Rieber 1/1 Teppanyaki Thermoplate.

The 1/1 format ensures maximum energy efficiency because the entire surface of the 1/1 heated pan is used.

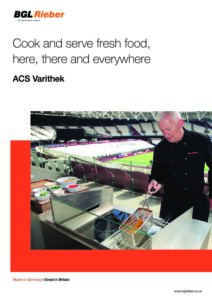

A typical restaurant uses modules in standalone formats – for front cooking or hot holding – and within the ACS Varithek with its self-ventilation. The modules and the Varithek ACS are fully mobile and quickly moved front or back of house.

Self-ventilation means Varithek ACS can be used anywhere without overhead ventilation systems.

Kitchen designers and catering equipment distributors choose Rieber Varithek ACS to fit into spaces with low ceiling heights, which would otherwise be unsuitable for cooking purposes without self-ventilation. Its also ideal for creating a front cooking kitchen anywhere, such as within large venues, stadia, hospitals, universities, airports etc.

The added fire suppression option means Varithek ACS can be used anywhere without setting off fire alarms.

Reusable GN induction pans

Digital reusable GN induction pans are causing quite a stir!

By prepping, cooking, storing, transporting and reheating food in one pan only, the kitchen saves labour, handling, washing etc.

Using (Thermoplate) multi-layer pans ensures faster and more even heating or cooling, reduces cook times or refrigeration cycles, and saves energy.

Digitising GN induction pans

– adding a QR code label – identifies the pan, lid, contents, dates/times and customer/user. This system ensures the pan is returned after delivery. Digitising speeds up orders and delivery. The QR label is also used with SMART cooking or reheating equipment/ovens, etc, which can scan the label to determine cook times.